1. What is the working process of Pig automatic feeding system?

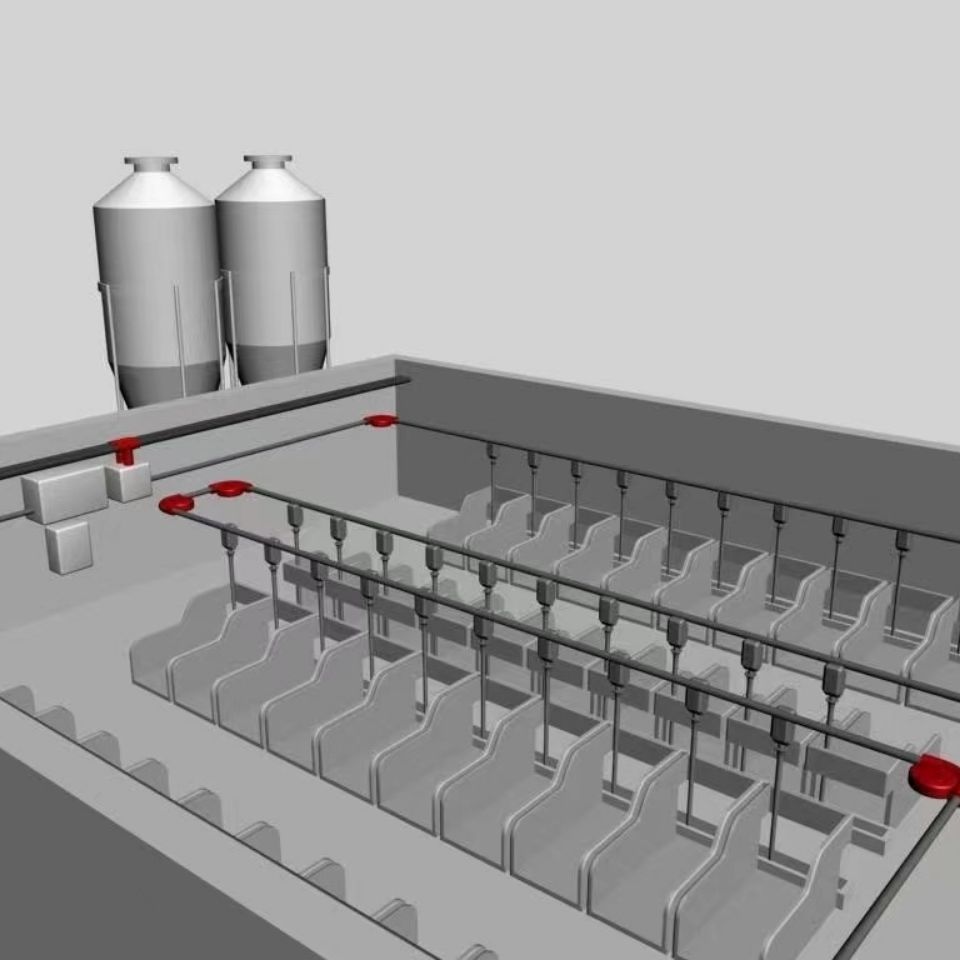

1. Pig automatic feeding system for Marshine swine farm automatic feed line is the sensor automatically detects the material level in the chute. 2. When the chute is short of material, under the control of the microprocessor, start the feed motor and the feed trough starts to feed. When the material in the chute is full, the sensor detects that the material is full, and the feeding motor stops feeding. 3. The silo can hold 4000 kg of feed and is fed by the feeding material feeding silo. When the silo is short of material, the control box emits sound and light alarms, prompts the workers to feed, and when the silo is full, the control box has LED indications stop feeding. 4. The automatic feeding system can realize full-automatic operation, reduce the labor intensity of the workers and increase the production efficiency of the farm.

2. What are the pig automatic feeding system line components?

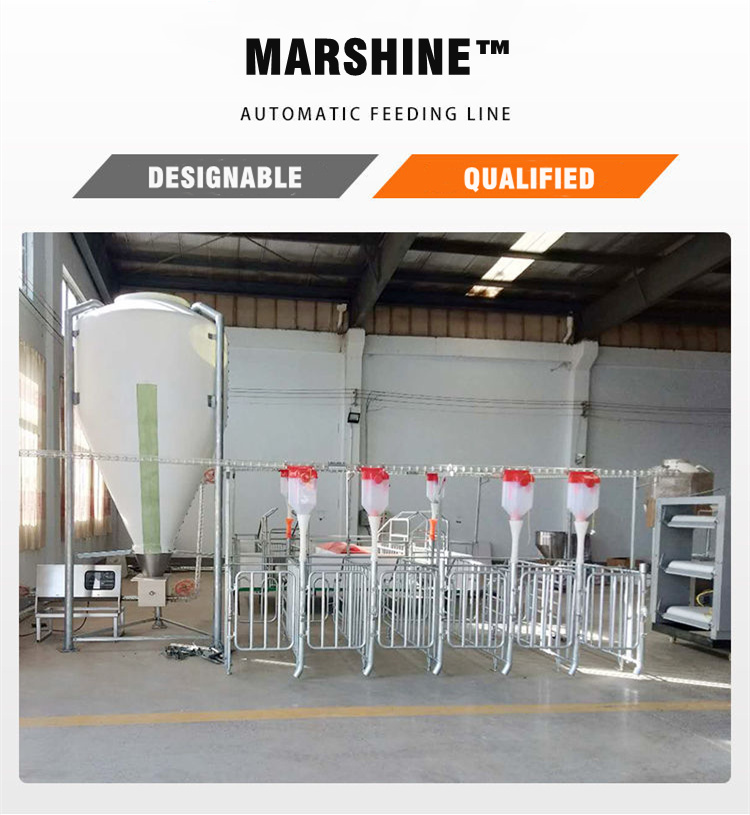

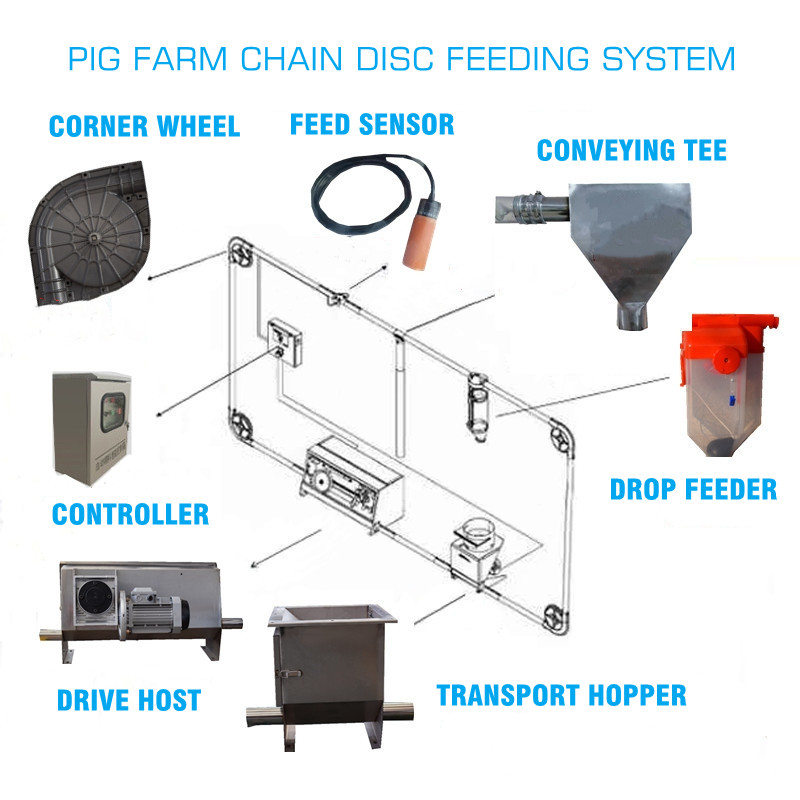

Components include: Feed Silo Tower, Main drive host, Chain disc, Fodder nest hopper, Plastic feed drop tee, Corner wheel, pig drop hopper, fodder level sensor, Double-sided feed trough 1.Feed Silo Tower Composed of tower main body, cover cap, climb ladder and support post. Material of silo can be hot-dip galvanized or fiberglass. Marshine Fiberglass material feeding tower shell is made by fully glass fiber and unsaturated resin, inner ribs made of non-alkali fiberglass 4 layers total thickness up to 6mm. 6 nos. support post 25mm thickness HDG pipe, lower cone have water hole to check the fodder level.

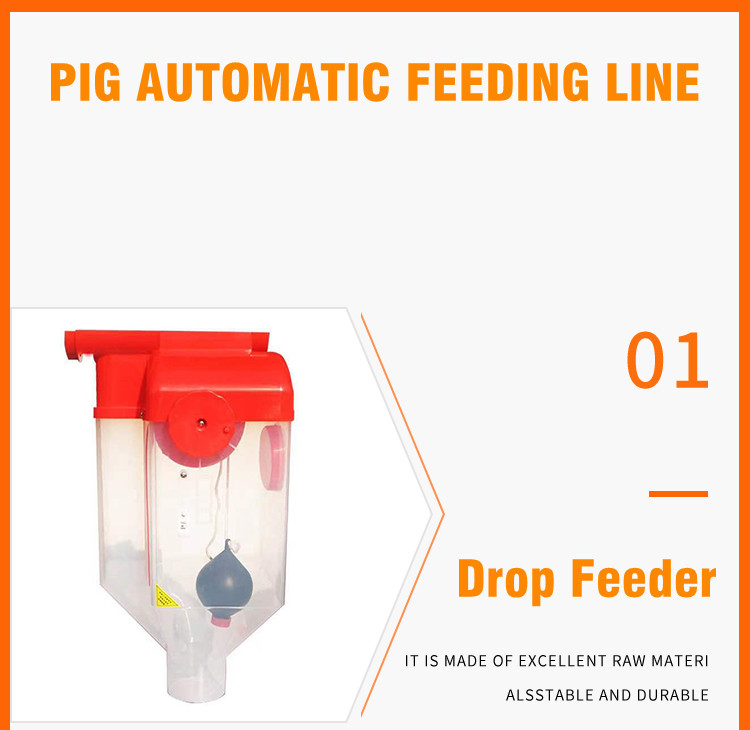

1.Feed Silo Tower Composed of tower main body, cover cap, climb ladder and support post. Material of silo can be hot-dip galvanized or fiberglass. Marshine Fiberglass material feeding tower shell is made by fully glass fiber and unsaturated resin, inner ribs made of non-alkali fiberglass 4 layers total thickness up to 6mm. 6 nos. support post 25mm thickness HDG pipe, lower cone have water hole to check the fodder level.  2. Pig drop hopper The new style Marshine pig drop hopper is easy installation and control the forage feeding easy, and save more feedstuff. Feed volume for each drop feeder can be adjusted by pulling and pushing adjustable slide up and down. Individual shut-off can make one certain drop feeder closed when there is no pig as feed goes.

2. Pig drop hopper The new style Marshine pig drop hopper is easy installation and control the forage feeding easy, and save more feedstuff. Feed volume for each drop feeder can be adjusted by pulling and pushing adjustable slide up and down. Individual shut-off can make one certain drop feeder closed when there is no pig as feed goes.

3. Fodder nest hopper Fodder nest hopper made of stainless steel, nest body thickness 2 mm and installed under the feed silo directly. With screening and vibration device, the dropping amount of feed can be controlled by the closing slide switch.

3. Fodder nest hopper Fodder nest hopper made of stainless steel, nest body thickness 2 mm and installed under the feed silo directly. With screening and vibration device, the dropping amount of feed can be controlled by the closing slide switch.  4. Plastic feed drop tee Plastic feed drop tee is special used for Marshine pig automatic feeding system for conveying feed. It has good sealing performance and strength easily cleaning and disassembly. When the double-face feeding for outlet drop, the angle should be less than 45 degree and the opening hole should be slightly tilted.

4. Plastic feed drop tee Plastic feed drop tee is special used for Marshine pig automatic feeding system for conveying feed. It has good sealing performance and strength easily cleaning and disassembly. When the double-face feeding for outlet drop, the angle should be less than 45 degree and the opening hole should be slightly tilted.  5. Main drive host Main drive host shell is stainless steel, corrosion resistance, install in-door and out-door are both available. Casted aluminum cycloid pin gear light weight, good heat radiation take up small space. Three phase induction motor, high starting torque, low noise, low vibration and long service life. Have automatic tension device, safety protection device when chain rupture or broken automatic stop the transportation. Marshine system integrated drive system, good structure and high output large torque and stable transmission reliable working.

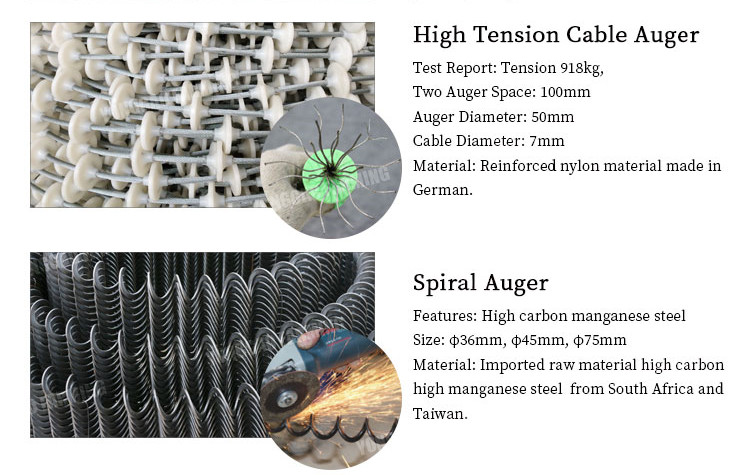

5. Main drive host Main drive host shell is stainless steel, corrosion resistance, install in-door and out-door are both available. Casted aluminum cycloid pin gear light weight, good heat radiation take up small space. Three phase induction motor, high starting torque, low noise, low vibration and long service life. Have automatic tension device, safety protection device when chain rupture or broken automatic stop the transportation. Marshine system integrated drive system, good structure and high output large torque and stable transmission reliable working.  6. Chain disc Chain disc made from nylon material conveying chain 20# high manganese steel Use high standard production technique to produce the chain dist, connected with 20# high manganese steel injected molding. Chain disc diameter 36mm/40mm/45mm use for 48mm and 60mm feeding pipe.

6. Chain disc Chain disc made from nylon material conveying chain 20# high manganese steel Use high standard production technique to produce the chain dist, connected with 20# high manganese steel injected molding. Chain disc diameter 36mm/40mm/45mm use for 48mm and 60mm feeding pipe.  7. Corner wheel Corner wheel shell is made of cast aluminum alloy or Nylon or synthetic material or Air inlet PC , also be installed with transparent shell which is the observation of feed delivery and good tightness, high strength, corrosion resistance, waterproof, aging resistance.

7. Corner wheel Corner wheel shell is made of cast aluminum alloy or Nylon or synthetic material or Air inlet PC , also be installed with transparent shell which is the observation of feed delivery and good tightness, high strength, corrosion resistance, waterproof, aging resistance.  8. Double-sided feed trough Double-sided feed trough from Marshine is designed with stainless steel material thickness of 1.5 mm. The trough is installed in the twin nursery bed, and it has two sides with multiple positions, which can meet the demands of two group of pigs, improve the feed conversion rate, reduce the waste of feed, an additional 5%

8. Double-sided feed trough Double-sided feed trough from Marshine is designed with stainless steel material thickness of 1.5 mm. The trough is installed in the twin nursery bed, and it has two sides with multiple positions, which can meet the demands of two group of pigs, improve the feed conversion rate, reduce the waste of feed, an additional 5%

3. What is the specification of pig automatic feeding system line?

| Name | automatic pig feeder, automatic Pig Feeding System |

| Material | Top quality for every part |

| Application | Pig farm, sow farm, piglet farm, hog farm, swine farm, automatic pig equipment |

| Type | Full automatic, the whole feeding system include drive system, deliver system, transmission system, feed drop system |

| Capacity | customized size based on your farm size, one line could feed 600pcs sow or more |

| Feature | Save time, save breeding cost, modern pig house, low cost high output |

| Installation | Professional engineer installation guide |

| Feeding Time | Automatic feeding within 30 minutes for 300pigs |

| Automatic Type | time set, quantity set, make sure feeding automatically, could set the time and feeding quantity , automatically feeding at different time. |

| Marshine offer professional pig farm design advice, help you to build your full automatic modern pig farm, choose us, save time, save cost for high quality system | |

| Type | pipe type | max length one driver | line | normal suitable | popularity | price |

| auger feeding system | pvc | 70m | straight line | any stall | higher | low |

| chain cycle feeding system | metal steel | 200m | have corner | weaning, finishing stall | lower | medium |

4. What is the advantage of pig automatic feeding system line?

Our Marshine pig automatic feeding system line can be used for all kinds of pig farm, sow farm, farrowing farm, piggery farm, fatten farm, Swine Farm, Hog Farm etc 1. Achieved automatic with feeding and data system statistics. Eating time and eating amount are controlled 2. The whole Marshine feeding system include drive system, deliver system, transmission system, feed drop system 3. Install in the big pig farm, easy to install, normally 3kg/day feeding for each pig, with water running while eating. 4. Pig farm cover sow breeding farm, piglet breeding farm, hog breeding farm, swine breeding farm, pig breeding farm 5. Save time, save breeding cost, one breeder can feed 600 to 1200 heads sow. 6. Could set the time and feeding quality to automatically feeding at different time. 7. Quickly feeding save 50% labor wages 300pigs finish feeding within 30 minutes 8. Automatically adjusting feeding amount according to different pig characteristics and pregnancy date.