1. What is FRP Explosion Proof Industrial Exhaust Fan?

Product Manufacturing process: FRP Explosion Proof Industrial Exhaust Fan refers to the fan made of glass fiber reinforced plastics (FRP).Its appearance and size and steel fan is exactly the same, but the shell and impeller are made of glass steel, Marshine has the characteristics of corrosion resistance, acid and alkali resistance, is a kind of anti-corrosion fan. Product material: FRP Explosion Proof Industrial Exhaust Fan shell is 10mm thickness. It will be very stability and durability. And the exhaust fan border thickness 18mm for comparably higher durability and strength installation. Marshine Fan impeller adopts frp SMC impeller, bending strength is not less than 196 Mpa, each part adopts smooth excessive, smooth appearance, no cracks, gaps, burrs and other defects, the overall effect is good, the fan has reasonable aerodynamics, large air volume, low noise, high efficiency, corrosion resistance.

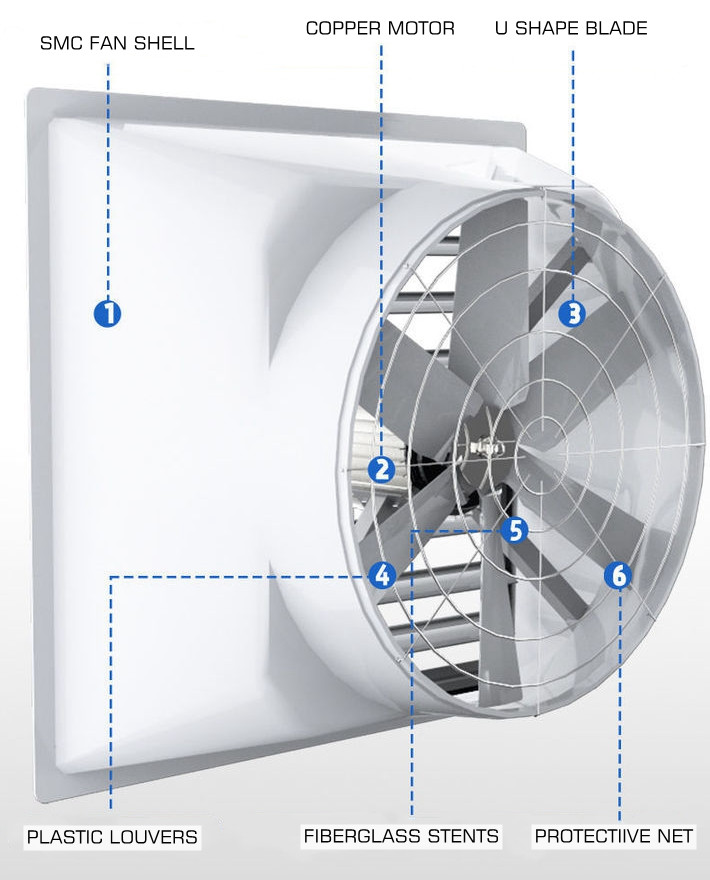

2. What are the essential components of FRP Explosion Proof Industrial Exhaust Fan?

FRP Explosion Proof Industrial Exhaust Fan is a new type of ventilation equipment made of FRP materials. Because the outer frame of the fan is made of anti-corrosion FRP, the FRP negative pressure fan can exchange air through negative pressure, which can achieve the purpose of air circulation, ventilation and cooling, so it is also called FRP negative pressure fan. Fan Frame Shell: The fan shell made of glass fiber reinforced plastic (FRP) is different from the ordinary fan. Marshine fan shell and impeller are made of glass fiber reinforced plastic. Its biggest characteristic is corrosion resistance and acid and alkali resistance. Louver or shutter: PVC shutter: Using the air downstream principle, this shutter is light weight and exhibits antioxidant properties, is light weight and is resistant to distortion. it can open and close swiftly which prevents backflow of air. Fan Blades: Adopt glass fiber reinforced plastic fan blade, no dust, special blade shape Ensure large air volume, no deformation, no fracture Pure copper wire motor. The motor adopts the national standard pure copper motor, fast speed, large power, has loss power protection device, protection class IP55, insulation class F Thicken Stents: high-strength ,low noise, durable. High-quality goods bearing. Imported Bearing : Good speed, low noise, not easy to rust High hardness, not easy to wear

Louver or shutter: PVC shutter: Using the air downstream principle, this shutter is light weight and exhibits antioxidant properties, is light weight and is resistant to distortion. it can open and close swiftly which prevents backflow of air. Fan Blades: Adopt glass fiber reinforced plastic fan blade, no dust, special blade shape Ensure large air volume, no deformation, no fracture Pure copper wire motor. The motor adopts the national standard pure copper motor, fast speed, large power, has loss power protection device, protection class IP55, insulation class F Thicken Stents: high-strength ,low noise, durable. High-quality goods bearing. Imported Bearing : Good speed, low noise, not easy to rust High hardness, not easy to wear

3. How does the size and types of the industrial exhaust fan?

| Item No. | Dimensions(mm) | Power(W) | Air Flow | Voltage/Frequency | Noise | Rotation Speed | Net Weight |

| 560# | 560x560x440mm(22”x22”x17”) | 250W (3p) | 10000 m³/h 5900CFM | 380V/50Hz (customizable) | ≤45db | 950rpm | 35kg |

| 680# | 680x680x450mm(26"x26"x18”) | 250W (5p) | 12000 m³/h 7200CFM | 380V/50Hz (customizable) | ≤45db | 820rpm | 40kg |

| 850# | 850x850x480mm(33"x33"x19”) | 370W (8P) | 17000m³/h 10000CFM | 380V/50Hz (customizable) | ≤53db | 620rpm | 45kg |

| 1060# | 1060x1060x550mm(42"x42"x22”) | 550W (10P) | 28000m³/h 16600CFM | 380V/50Hz (customizable) | ≤55db | 560rpm | 50kg |

| 1260# | 1260x1260x560mm(50"x50"x22”) | 750W (10P) | 37000m³/h 22000CFM | 380V/50Hz (customizable) | ≤65db | 520rpm | 65kg |

| 1460# | 1460x1460x580mm(57"x57"x23”) | 1.1KW(10P) | 45000m³/h 26500CFM | 380V/50Hz (customizable) | ≤65db | 450rpm | 75kg |

4. What Is The Purpose Of Explosion Proof Industrial Exhaust Fan For Wall Ventilating System?

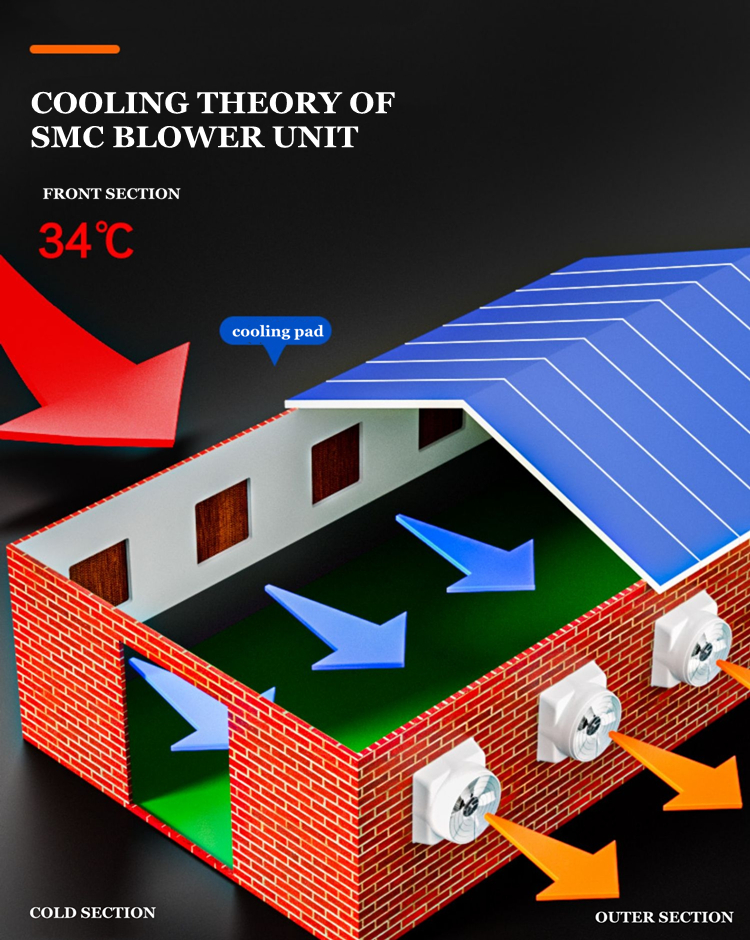

Features of FRP Explosion Proof Industrial Exhaust Fan: The whole Marshine fan adopts CAD/CAM design, which has the characteristics of low investment cost, large air volume, low noise, small energy consumption, stable operation, long life and high efficiency. The louver automatically rises and closes to be dustproof, waterproof and beautiful. It is the best choice for cooling and ventilation in modern workshop. Environmental protection, energy - saving negative pressure fan will become the ventilation cooling equipment market mainstream. The role of FRP Explosion Proof Industrial Exhaust Fan: 1, For ventilation: installed outside the window of the workshop, generally choose the air outlet, outward ventilation, out of the peculiar smell gas; General chemical plants and other applications more. 2. Use with wet curtain: it is used for the hot summer, no matter how hot your workshop is, the wet curtain - negative pressure fan system can make the temperature of your workshop drop to about 30℃, and there is a certain humidity.

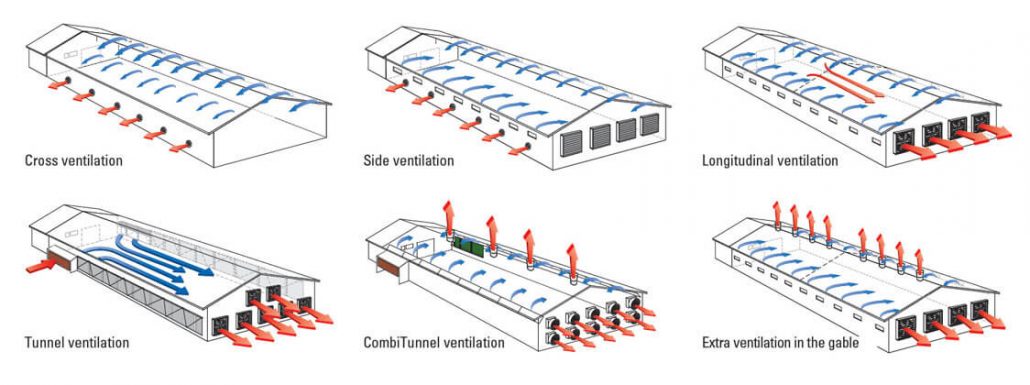

5. How To Selecting the Right Fans For Poultry House Industrial Ventilation Systems?

Side Ventilation Fans: A poultry house is usually equipped with a side fan (small fan) for the fundamental purpose of maintaining the minimum ventilation volume in it. The number of side fans = the minimum ventilation volume at the maximum weight of the flock in the poultry house ÷ the ventilation volume of the fan For example, to build a poultry house holding 30,000 chickens, if the maximum average weight of each is 3 kg, then the number of side fans = 30,000 × 3 kg/each × 0.0155 cubic meters/minute. kg (minimum ventilation coefficient) ÷ the ventilation volume of the fan Taking into account Marshine fan volume losses caused by various reasons, therefore, 1-2 more fans must be installed in actual practice. Longitudinal Ventilation Fans: The number of longitudinal fans to be installed is related to the high temperature in summer. In hot summer, the air cooling effect can be achieved by increasing the wind speed in the poultry house, thereby reducing the sensible temperature of the flock. The number of longitudinal fans = the cross-sectional area of the poultry house × the desired wind speed ÷ the ventilation volume of the fan (due to regional differences, the temperature and humidity in summer in each region are different, so the desired wind speed varies as well) For example, if the poultry house is 100 meters long, 14 meters wide, and the sidewall is 2.5 meters high, the roof is 4 meters high, and the desired wind speed is 2.5 meters per second, then the number of longitudinal fans = 14 meters × {2.5 meters + (4 meters- 2.5 meters) ÷ 2} × 2.5 meters/second × 60 seconds/minute ÷ ventilation volume of the fan