Material

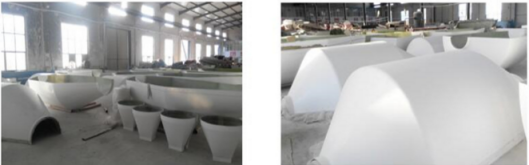

1. High-performance fiber reinforced polymer 2. Inner ribs made of non-alkali fiberglass 4 layers 3. Light weight 4. High hardness 5. Corrosion resistance 6. Good insulation performance 7. Protect feed from mildew caused by high temperature, strong heat, rain 8. Long service more than 20 years.

1. High-performance fiber reinforced polymer 2. Inner ribs made of non-alkali fiberglass 4 layers 3. Light weight 4. High hardness 5. Corrosion resistance 6. Good insulation performance 7. Protect feed from mildew caused by high temperature, strong heat, rain 8. Long service more than 20 years. Color

1. White gel cover 2. Anti ultraviolet 3. Excellent performance on thermal

1. White gel cover 2. Anti ultraviolet 3. Excellent performance on thermal Thickness

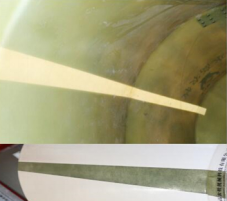

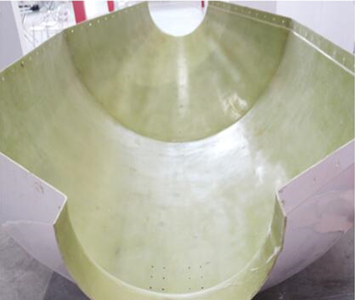

1.Integral molding, compare with traditional hand lay-up, whole silo keep uniform thickness. 2. thickness up to 6mm 3. heat curing demoulding make sure no bubble inside, insure long service life Hardness & Intensity 1. Barcol hardness: 42HBa 2. Tensile intensity: 195MPa 3. Bending intensity: 230Mpa 4.Impact intensity: 278KJ/m2

1.Integral molding, compare with traditional hand lay-up, whole silo keep uniform thickness. 2. thickness up to 6mm 3. heat curing demoulding make sure no bubble inside, insure long service life Hardness & Intensity 1. Barcol hardness: 42HBa 2. Tensile intensity: 195MPa 3. Bending intensity: 230Mpa 4.Impact intensity: 278KJ/m2 Hardness & Intensity

1. Inspection window 2. Width 10cm,cover whole body 3. Easy to check the storage of the feed, save much labor cost.

1. Inspection window 2. Width 10cm,cover whole body 3. Easy to check the storage of the feed, save much labor cost. Surface Gloss

1. Gloss: 90 2. Super smooth inside and outside surface 3. No feed hang on ,no feed residue

1. Gloss: 90 2. Super smooth inside and outside surface 3. No feed hang on ,no feed residue Hardness & Intensity

1. Inspection window 2. Width 10cm,cover whole body 3. Easy to check the storage of the feed, save much labor cost.

1. Inspection window 2. Width 10cm,cover whole body 3. Easy to check the storage of the feed, save much labor cost. Cover

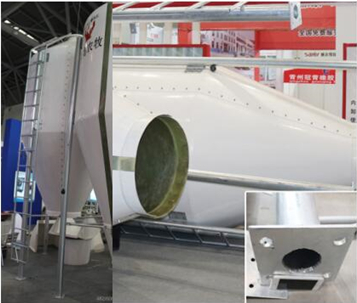

1.Tight sealing 2. Long steel connect with top to cover, people could open the cover on the ground.

1.Tight sealing 2. Long steel connect with top to cover, people could open the cover on the ground. Bracket

1. Hot dip galvanized bracket 2.Tube diameter 102mm, thickness 3mm 3. Safe ladder design

1. Hot dip galvanized bracket 2.Tube diameter 102mm, thickness 3mm 3. Safe ladder design Installation

1.Integral moulding 2. Right and left part, connect with SS bolt. 3. Easy to installFIBERGLASS SILO MAPLEFRP Glass fiber reinforced plastic feeding tower shell is made by fully glass fiber and unsaturated resin. It possessed strong body, light weight, non-toxic, non-pollution, high quality feeding, smooth surface, low noise, sealed transform, and simple installation.

1.Integral moulding 2. Right and left part, connect with SS bolt. 3. Easy to installFIBERGLASS SILO MAPLEFRP Glass fiber reinforced plastic feeding tower shell is made by fully glass fiber and unsaturated resin. It possessed strong body, light weight, non-toxic, non-pollution, high quality feeding, smooth surface, low noise, sealed transform, and simple installation. Advantages

1. High-quality galvanization of all steel parts and use of fiberglass reinforced plastic (FRP) = long service life; 2. Trouble-free feed withdrawal due to optimum degree of slope in the silo funnel; 3. Auger box rigid or flexible, adjustable from 0 to 45° – ensures operational safety; 4. Roof shape ensures use of the entire volume; 5. The use of FRP silos allows simple checking on feed level due to the transparency of the material; 6. High functional reliability.| Material | Fiberglass | Galvanized |

| Heat insulation | better, keep the feed goodunder any condition of weather(high temperature or humid weather) | not good, if humid weather,water would grow inside,pollute the feed |

| Technology | Integrated Molding, super smoothsurface | Spliced assembly, feedwould be hung on bolt |

| Maintenance | water, or high pressure gas | feed agglomerate, needanti rust regularly |

| Service Time | more than 20 years | 5-10 years |

| Item | Steel silo | FRP silo | Result |

| mechanical strength | 1-2mm | 5-10mm | higher strength |

| heat conductivity | 48/w.m.K | 5 /w.m.K | feed temperature don't change quickly |

| Anti-UV | 0 | yes | prevent your feed from going bad |

| Rust | 5-10 years | 30 years | never rust |

| Type | Capacity (m3) | Ton | Legs | Silo pcs | A | B | h | C | D | E | F | Foundation size |

| 080400 | 4 | 2.4 | 3 | 2 | 3516 | 1080 | 745 | 300 | 1800 | 3000 | 1688 | 3000x3000x300 |

| 080600 | 6 | 3.6 | 3 | 2 | 4190 | 1187 | 850 | 300 | 2020 | 3000 | 1866 | 3000x3000x300 |

| 080800 | 8 | 4.8 | 3 | 2 | 4850 | 1120 | 785 | 300 | 2080 | 3000 | 1930 | 3000x3000x300 |

| 081000 | 10 | 6 | 3 | 2 | 5025 | 1095 | 757 | 300 | 2250 | 3000 | 2075 | 3000x3000x300 |

| 081250 | 12.5 | 7.5 | 3 | 2 | 5690 | 1100 | 745 | 300 | 2215 | 3000 | 2060 | 3000x3000x300 |

| 081800 | 18 | 10.8 | 4 | 3 | 6955 | 1374 | 1038 | 400 | 2492 | 4000 | 1883 | 4000x4000x400 |

| 082000 | 20 | 12 | 4 | 3 | 7265 | 1314 | 977 | 400 | 2492 | 4000 | 1883 | 4000x4000x400 |

| 082150 | 21.5 | 13 | 4 | 3 | 7420 | 1314 | 977 | 400 | 2590 | 4000 | 1955 | 4000x4000x400 |

| 082450 | 24.5 | 14.5 | 4 | 3 | 7960 | 1290 | 955 | 400 | 2600 | 4000 | 1960 | 4000x4000x400 |

| 082500 | 25 | 15 | 4 | 3 | 8150 | 1115 | 778 | 400 | 2492 | 4000 | 1883 | 4000x4000x400 |

| 083000 | 30 | 18 | 4 | 3 | 8895 | 1125 | 790 | 400 | 2590 | 4000 | 1955 | 4000x4000x400 |